Pneumatic cylinder(s) (sometimes known as air cylinders) are mechanical devices which use the power of compressed gas to produce a force in a reciprocating linear motion. Like hydraulic cylinders, something forces a piston to move in the desired direction.

The word pneumatic means related to air. Many will be familiar with the pneumatic tubes that use air pressure to send documents to the teller at a bank drive-through. Similarly, pneumatic cylinders use air pressure differentials to produce force and motion, resulting in work.

The Facts

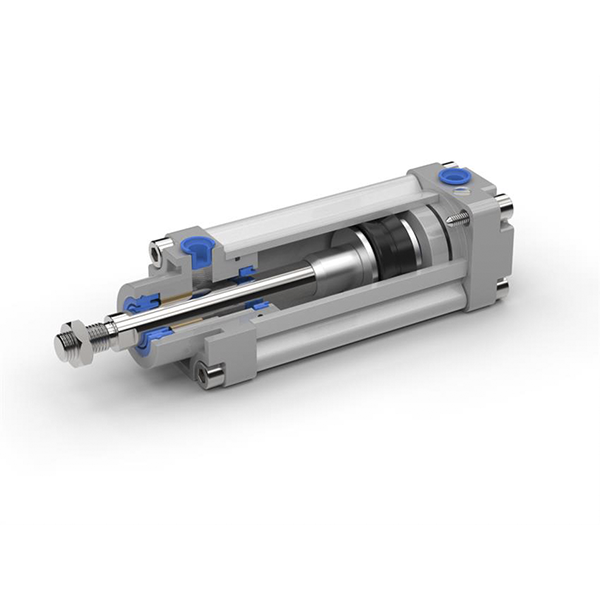

Pneumatic cylinders convert the potential energy of compressed air into mechanical energy of applied force or the kinetic energy of motion. Within the cylinder, two chambers are maintained at different air pressures. A piston, sometimes called a rod, attached to the dividing wall is set in motion as the volume of the chambers changes in response to the relative pressure of the two chambers. At least one of the chambers is connected to a port that allows for the flow of air in and out of the cylinder.

Features

Different pneumatic chambers will have different operating specifications. Two key features are cylinder stroke, which is the distance between fully extended and fully retracted piston positions, and the operating pressure range. The pressure range reflects the minimum amount of pressure required to actuate the cylinder and the maximum pressure it can safely contain, and determines the amount and nature of work the cylinder can perform. Another important feature is the mounting options for the device, which ultimately determine how the cylinder can be incorporated into a larger mechanical system.

Function

In most cases, the immediate action of an air cylinder is to drive a piston, and so, ultimately, the function of the entire machine can be anything that’s operated or actuated by the movement of piston. Pneumatic systems can push and pull, lift objects, open and close doors, or hold, remove and position parts in manufacturing by producing a clamping action. Air cylinders appear frequently in materials handling and processing and in fail-safe systems where airtight seals are necessary.

Types

The major distinction between pneumatic cylinders is whether they are single acting cylinders (SAC) or double acting cylinders (DAC). SAC use the force of air pressure to move a rod in a single direction, usually away from the cylinder. In these mechanisms a spring returns the piston to the original position when the air pressure is released. In DAC, air pressure is used in both the extension and retraction strokes, allowing for detailed operation in both directions. DAC have two ports, one to control each stroke.

Identification

When identifying a particular pneumatic cylinder, it is also helpful to identify the kind of motion it generates and the type of casing in which the piston is contained. The typical generic air cylinder is a smooth-body rectangular cylinder, meaning the piston is entirely encased in a box-shaped frame. In a pancake cylinder, the casing’s diameter is much larger than its thickness, resulting in a flat, round cylinder that doesn’t necessarily house the entire piston rod. A rotary cylinder is designed so that the air pressure actuates a rotating motion. Finally, multiple-bore cylinders can create motion in more than one piston at a time, each designed and positioned for a unique task.