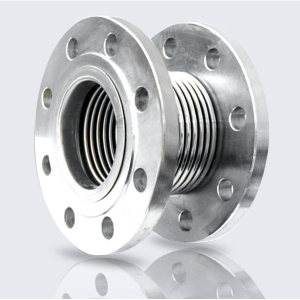

Lens expansion joints are single-walled metal expansion joints in single or multi-shaft variations with lowerexpansion and very robust construction. These consist of one or several semi-circles that are welded into corrugation peaks and troughs with circular seams. Lens expansion joint parameters. Bellows materials.

Lens expansion joints are the custom requirements in cases where the application requires a single layer bellow. If the material thickness

of the single layer bellow is more than 4 mm, the supply of a normally manufactured bellow is no longer possible. In this case, lens expansion joints are the optimum solution. Normally issues concerning material thickness are solved by the supply of a multilayer bellow but in some cases, this is not accepted by the customer and/or the application.

Lens expansion joints are constructed as illustrated on the drawings below.

As it is shown, lens expansion joints are supplied either as a half convolution, a complete convolution or as a bellow. According to the customer’s requirements, these are either delivered already welded together or they can be

welded together on-site.

What are the advantages of using Lens expansion joints?

Lens expansion joints are preferred in all industries that uses pressurised equipment and heat exchangers and where the higher pressure and higher temperature require greater material thickness.

Lens expansion joints are the custom requirements in cases where the application requires a single layer bellow. If the material thickness

of the single layer bellow is more than 4 mm, the supply of a normally manufactured bellow is no longer possible. In this case, lens expansion joints are the optimum solution. Normally issues concerning material thickness are solved by the supply of a multilayer bellow but in some cases, this is not accepted by the customer and/or the application.