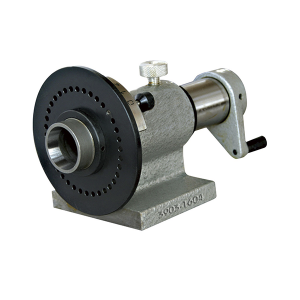

Workpieces are held to the headstock spindle of the lathe with chucks, faceplates, or lathe centers. A lathe chuck is a device that exerts pressure on the workpiece to hold it secure to the headstock spindle or tailstock spindle. Commonly used with the lathe are the independent chuck, the universal scroll chuck, the combination chuck, the hollow headstock spindle chuck, the lathe tailstock chuck, the collet chuck, and the step chuck.

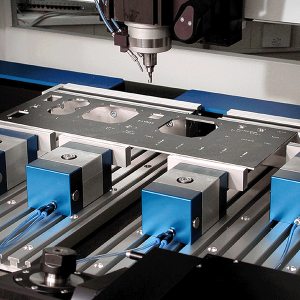

General – Workpieces often need extra support, especially long, thin workpieces that tend to spring away from the cutter bit. Two common supports or rests are the steady rest and the follower rest.

Steady Rest – The steady rest or center rest, as it is also called, is used to support long workpieces or shafts being machined between centers or for boring operations. It is also used for internal threading operations where the workpiece projects a considerable distance from the chuck or faceplate. The steady rest is clamped to the lathe bed at the desired location and supports the workpiece within three adjustable jaws. The rest prevents the workpiece from springing under cut, or sagging as a result of the otherwise unsupported weight.

The workpiece must be machined with a concentric bearing surface at the point where the steady rest is to be applied. The jaws must be carefully adjusted for proper alignment and locked in position. The area of contact must be lubricated frequently. The top section of the steady rest swings away from the bottom section to permit removal of the workpiece without disturbing the jaw setting.