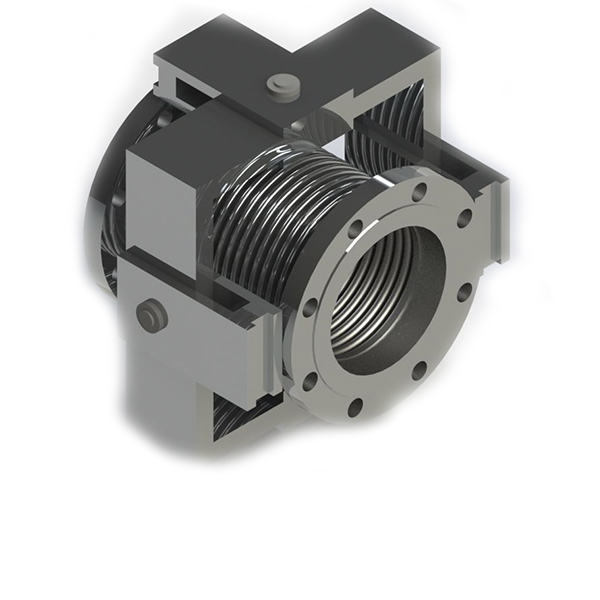

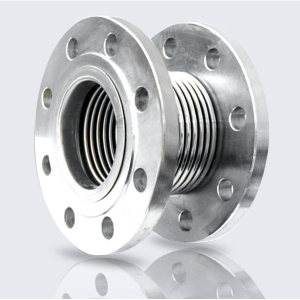

Gimbal expansion joints are designed to accept angular movement in any plane.Gimbal expansion joints are usually used in pairs or in system of one pair of gimbal expansion joints plus one hingedexpansion joint.

The gimbal pipe expansion joint is basically same as the hinge type, except that instead of being limited to deflection in only one plane gimbal Expansion Joints are used to absorb angular rotation in any plane, using two pairs of hinges attached to a common floating gimbal ring.

Gimbal systems generally consist of two gimbal expansion joints or two gimbal and one hinged expansion joint/bellow.

The advantages of this type of construction is it provides a close control over the movement imposed up on the bellows and also supports the dead weight of the pipe.

In addition, the wind and shear loads are also taken care of by the gimbal structure.

Gimbal bellows joints are designed to absorb the full pressure thrust load of the expansion joint and thus guard the adjacent equipment from damage due to thrust loading.

Since gimbal bellows joints are not restricted to a single plane they offer greater flexibility of usage.

The use of gimbal bellows joints results in the best system which eliminates the effects of thermal growth and lowers both reaction forces and installation costs. Expensive main anchors are eliminated and only minimal guiding is required.

Main features of Gimbal Expansion Joint:

– Permits angular movement in any plane

– Eliminates pressure thrust forces

– Transmits shear and wind loads, so low forces on the pipe anchors

– No main anchors required

– Prevents torsion or twisting of the expansion joint

– Internal flow liners for eliminating velocity problem

– Anchors only required to absorb spring forces

– Low forces on piping system

Main features of Gimbal Expansion Joint:

– Permits angular movement in any plane

– Eliminates pressure thrust forces

– Transmits shear and wind loads, so low forces on the pipe anchors

– No main anchors required

– Prevents torsion or twisting of the expansion joint

– Internal flow liners for eliminating velocity problem

– Anchors only required to absorb spring forces

– Low forces on piping system

Advantages of Gimbal Expansion Joint:

– Absorbs angular movements in all planes and angular rotations, or any combinations of these

– Eliminates pressure thrust loads

– Positive control over the movements

– Supports dead weight of the intermediate piping

– Transmits external loads like wind loading and shear loading

– Prevents torsion on the bellows elements

– Guiding requirement is minimized

– Eliminates main actors

Limitations of Gimbal Expansion Joint:

– More space is required for gimbal bellows joints as compared to axial expansion joints

– Change of pipe direction is required

– Two or more gimbal expansion joints required to work as a system

Applications of Gimbal Expansion Joint:

– Engines

– Steel mills

– Petro Chemical

– Power Generation

– Shipbuilding industry

– Water treatment

– Cement plants

– Paper industry