A flowmeter takes both knowledge of the types of meters available and the kind of empirically derived knowledge that comes from experience. If you are like most people, you first think about the types of meters, their features, and their hardware and software. You might start to build the meter from the application requirements. You might list all the types of flowmeters and then pick one. The first cuts are obvious: liquid, solid, air, gases. Each cut separates out huge numbers of flowmeter types. Let’s say your flow is liquid.

We are going to review the types of flow devices, look at selecting a flow device, and examine the real-world basics of flowmeter installation. Then, I hope you’ve brought your favorite flowmeter problem, because the doctor is IN.

There are lots of flow devices, for both liquids and gases, and for closed and open channels. We’ll look at some of the most common devices, and focus on some simple ways to select and use them. Note that there are at least 10 different types, and they don’t all work on all applications.

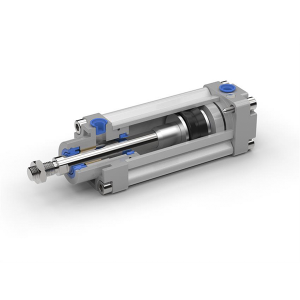

Positive displacement meters are used for both liquids and gases and are nearly always highly accurate. They come in a variety of types, such as oval gear, reciprocating piston, nutating disc, and rotary piston. They all work by emulating a bucket. One bucket in, one bucket out.

Differential pressure-based flow measurement is still the widest used technique throughout the process industries. Why? It is simple, inexpensive, and is accomplished by pressure transmitters, which the plant usually has for other measurements (pressure and level) anyway.

Turbines, paddlewheels, impellers, propellers . . . there are a wide variety of types and styles of volumetric mechanical meters, but they all work by converting the speed of a rotor to a volumetric flow value. They can be highly accurate (1 percent of reading) or only approximate (5 percent of span). They can be spool-piece style, bar-stock style, or insertion devices. They range from inexpensive to medium priced to fairly expensive models with high precision and special materials.

Because they measure the average velocity in the fluid directly, spool-piece magmeters can accurately measure flow. Other flow technologies that can rival a magmeter for installed accuracy include correlation-type ultrasonic flowmeters with calibrated spool pieces, and of course, Coriolis mass flowmeters. Note, however, that a point-velocity insertion magmeter is only about as accurate as a paddle wheel meter, because it only measures flow in a small cross-sectional area of the pipe.

Ultrasonic flowmeters are the most misapplied flowmeters around. When they were first introduced, they were supposed to replace all other types. But what happened is that they, too, found their niche. The “Prince Charming” of flowmeters has not yet come. Both transit time and Doppler ultrasonic flowmeters are now available.

Thermal dispersion is also used for highly accurate flowmeters in low-flow applications and can even be used for mass flow of gases. Considerable care, though, needs to be taken for applications like these. Beware of abrupt changes in fluid temperature.

Vortex shedding meters and other fluidic types have no moving parts and use the fluid itself the way a turbine uses its rotor. A traditional vortex shedding meter uses a bluff body (often called a shedder bar) to produce the repeatable oscillation. A swirl meter uses a stationary “rotor-like” device to twist the flow and a restriction to contain and make the oscillation repeat. They can be installed with little or no upstream straight run. Coanda-effect flowmeters use hydraulic feedback to force the fluid to oscillate in proportion to its velocity.

If I were told that I could pick only two types of flowmeters to use, forever, and that I would be judged based solely on the accuracy of the measurement, I would surely pick a Coriolis mass flowmeter as one of the two. A spool-piece style magmeter would probably be the other one.

In an open channel application, the “flowmeter” is the flow restriction itself: the flume or weir. The instrument is only the level sensor that automates the meter reading. You can use a yardstick and be quite accurate.