Fixture Plates & Columns. Fixture columns, also known as tooling columns or tombstones, are lightweight workholding solutions that can be used on a rotary table or mounted directly onto a pallet. … All of our fixture columns are made from a high-strength aluminum alloy.

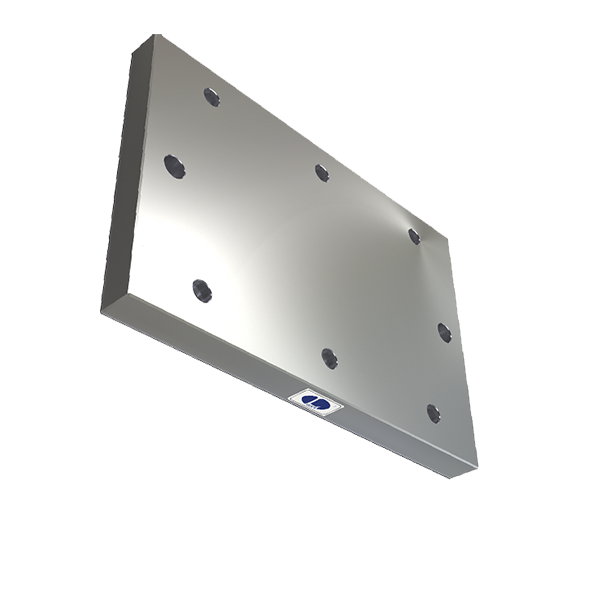

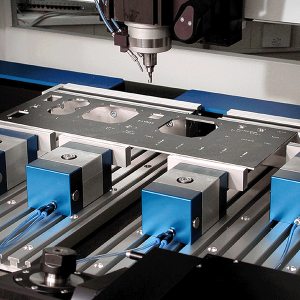

Tooling plates and columns provide mounting or clamping surfaces for holding and positioning vises, clamps and workpieces during setup, manufacturing and dimensional inspection.

Tooling plates are manufactured from a variety of materials, including:

– Aluminum

– Cast Iron

– Granite

– Stainless Steel

– Steel

In order to provide a flat, stable surface, the tooling plates and columns are typically stress relieved, machined, and ground or polished flat. Holes, slots or T-slots may be machined into the mounting surface as well to fixture clamps or workpieces.

Many types and shapes of tooling plates and columns are manufactured. Proper selection depends on the application.

Angle plates are used as work holding devices in machining, inspection and layout applications. Most angle plates are machined out of cast iron with square faces; however adjustable angle plates are also available. Angle plates typically have slots or T-slots used to assist in work holding.

A base plate is used as the foundation plate in machine tools and other heavy machinery.

A box cube, or clamping cube, is machined on all six sides and typically has slots for work holding on the top and all four sides.

Box brackets, or riser plates, have four ground surfaces with slots or openings for work holding and two open ends. They are used to raise clamps and locators parallel to the tooling plate to reach the workpiece.

Floor rails are mounted to the floor and contain holes for bridge or table mounting.

Pallet tooling plates are used as work holding surfaces on pallets used in palletized conveyors.