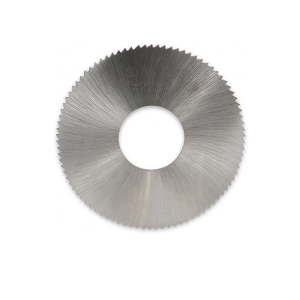

An end mill is a type of milling cutter, a cutting tool used in industrial milling applications. It is distinguished from the drill bit in its application, geometry, and manufacture. While a drill bit can only cut in the axial direction, a milling bit can generally cut in all directions, though some cannot cut axially.

The process of abrading materials has existed for thousands of years. Whether by hand or machine, materials have been cut, ground or crushed to create a wide-variety of products. Since the 1800s, this process has been referred to as “milling”.

Today, the milling process is entirely automated. Manufactured rotary cutters and drills are attached to a large milling machine and used to remove material from a given workpiece. Due to the unlimited selection of varying drill bits and illing ends, the milling process is capable of producing nearly anything, including, gun parts, circuit boards, jewelry and much more.

End milling primarily differs from other milling processes due to the type of tooling that is used for abrading a given material. Unlike cutters and drill bits, end mills have cutting teeth on the sides and end of the mill. Additionally, the milling applications for the end mill are unique. End mills are typically used in applications requiring profile milling, tracer milling, shape milling, face milling and plunging. For non-conventional or unique applications, CGS Tools specializes in designing .

To meet specific application needs, end mills are manufactured with different designs, materials, diameters, lengths, flutes, protective coatings, etc. Popular end mill designs, include:

– Roughing End Mills

– Finishing End Mills

– Square End Mills

– Ball End Mills

– Corner Rounding End Mills

Choosing an end mill is no simple task. Every business must consider which end mill best fits the desired application and results in minimum production costs.