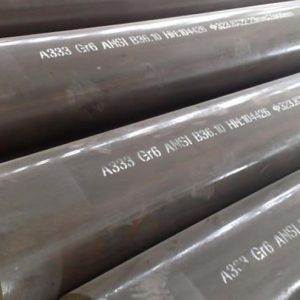

We offer a comprehensive range of ASTM 335 Alloy Steel Pipes & Tubes that are appreciated for superior quality and unmatched durability. These are available in different sizes, grades, specification and shapes. We can manufacture such as Seamless & Welded Pipes & Tubes as per ASME B16.11 standards & other international standards. These Alloy steel pipes & tubes are used in different application industry like oil refineries, chemical plants, fertilizers plants, petrochemicals plants and sugar mills etc. ASTM 335 Alloy steel pipes & tubes are offered at affordable prices by. They can customize this alloy steel pipes & tubes as per the requirements of the clients.

Alloy steels are made by combining carbon steel with one or several alloying elements, such as manganese, silicon, nickel, titanium, copper, chromium and aluminum. These metals are added to produce specific properties that are not found in regular carbon steel. The elements are added in varying proportions (or combinations) making the material take on different aspects such as increased hardness, increased corrosion resistance, increased strength, improved formability (ductility); the weldability can also change.

The most important and desired changes in alloy steel are:

Increased hardenability.

Increased corrosion resistance.

Retention of hardness and strength.

Nearly all alloy steels require heat treatment in order to bring out their best properties.

Alloying Elements & Their Effects

Chromium – Adds hardness. Increased toughness and wear resistance.

Cobalt – Used in making cutting tools; improved Hot Hardness (or Red Hardness).

Manganese – Increases surface hardness. Improves resistance to strain, hammering & shocks.

Molybdenum – Increases strength. Improves resistance to shock and heat.

Nickel – Increases strength & toughness. Improves corrosion resistance.

Tungsten – Adds hardness and improves grain structure. Provides improved heat resistance.

Vanadium – Increases strength, toughness and shock resistance. Improved corrosion resistance.

Chromium-Vanadium – Greatly improved tensile strength. It is hard but easy to bend and cut.