Valves

A valve is one device that directs, regulates or controls the flow of the fluid by opening, closing, or partially obstructing various passage-ways. Valves are technically kinds of fittings, but, are usually discussed as a separate category. In an open valve, fluids flow in a direction from higher pressure to lower.

Valves have many uses, which includes controlling water for irrigation, industrial uses of controlling processes, residential uses such as on/off and pressure control to clothe and dish washers and taps at homes. Even, aerosol has a tiny valve built in it. Valves are also used in military and transportation sectors. In HVAC ductwork and other near – atmospheric air flows, valves are instead called dampers. In compressed air systems, however, valves are used with the most common type ball valves.

Variations

Valves vary widely in application and form. Their sizes are typically in the range from 0.1mm -60cm. Also, special valves can have a diameter exceeding 5 meters or more.

The most common use of the term valve refers to the poppet valves which found in the vast majority of the modern internal combustion engines, such as, those in most fossil fuel powered vehicles.

Basic Types of Valves by Operating Principles

- Ball valve, on/off flow control without pressure drop

- Butterfly valve, on/off control in large diameter pipes

- Choke valve, raises or lowers a solid cylinder placed around / inside a second cylinder with holes or slots. Used for high pressure drops found in oil and gas well – heads

- Diaphragm, controls flow by movement of a diaphragm

- Gate valve, mainly for on/off control with low pressure drop

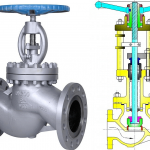

- Globe valves, good for regulating flow. Uses a cylinder movement over a seat

- Knife valve, similar to gate valves, but more compact. Used for slurries or powders on/off control

- Needle valve, for accurate lineer motion control

- Pinch valve, for slurry flow regulation and control

- Piston valve, for regulating fluids that carry solids in suspension

- Plug valve, slim valve for on/off control but with pressure drop

- Solenoid valve, an electrically actuated valve for hydraulic or pneumatic fluid control

- Spool Valve, pretty similar to the choke valve

Basic Types by Function

- Check valve, allows the fluid to pass in only one direction.

- Flow control valve, to maintain and control the flow rate through the valve

- Poppet valve, usually used in piston engine to regulate the fuel mixture intakes and exhausts

- Pressure reducing valve, to regulate the pressure of the fluid.

- Thermal expansion valve, used in air conditioning and refrigeration systems.

- Safety valve / relief valve, operates automatically to a set pressure to correct a potentially dangerous situation.

- Sampling valve

Specific Types

- Aspin valve: a cone – shaped metal part fitted to an engine’s cylinder head

- Ball cock: usually used as a water level controller

- Bib cock: provides a connection to a flexible höse – pipe

- Blast valve: prevents the rapid overpressuring in a fallout shelter or a bunker

- Boston valve: three – two port check valve used for inflatable boats, airbeds etc.

- Cock: colloquial term for a small valve or stopcock

- Ceramic Disc valve, used in high duty cycle applications or abrasive fluids

- Choke valve, used to limit air intake in internal combustion engine

- Clapper valve: Used in the Siamese fire appliance to allow only one hose to be connected

- Demand valve: Diving regulator

- Double beat valve

- Double check valve

- Duckbill valve

- Fill and drain valve: Used in space and missile industry which achieves extremely tight leakage, while providing redundant inhibits against external leakage

- Flapper valve

- Flow divider valve: Providing a plurality of output flows from a single fluid source

- Heimlich valve: a specific one – way valve used at the end of chest drain tubes to treat a pneumothorax

- Foot valve: a check valve on the foot of a suction line to prevent backflow

- Four – way valve: was used to control the flow of steam to the cylinder of early double – acting steam engines

- Freeze seal / Freeze plug: in which freezing and melting the fluid creates and removes a plug of frozen material acting as a valve

- Gas pressure regulator: regulates the flow and pressure of the gas

- Heart valve: regulates blood flow through the heart in many organisms

- Hydrodynamic vortex valve: a passive flow control valve that uses hydrodynamic forces to regulate flow

- Larner – Johnson Valve: needle control valve usually in large sizes used in water supply systems

- Leaf valve: one – way valve consisting of a diagonal obstruction with an opening covered by a hinged flap

- Pilot valve: regulates flow or pressure to other valves

- Pinch valve: simple, single – part two – port check valve made from soft plastic and molded on to inflatable units such as beach ball plug, air mattresses, water wings

- Plunger valve: Regulates the flow while lowering the pressure

- Poppet valve and sleeve valve: usually used in piston engines to regulate the fuel mixture intake and exhaust

- Pressure reducing valve

- Pressure sustaining valve: maintains pressure at a preset level upstream

- Quarter turn valve

- Presta, Schrader or Dunlop valves: Used to hold the air in tires

- Reed valve: consists of two flexible materials pressed together, but with the influx area open to allow one-way flow

- Regulator: used in SCUBA diving equipment and in gas cooking equipment to reduce the high pressure gas supply to a lower working pressure

- Rocker valve

- Rotolock valve

- Rotary valves and piston valves: Used to change their pitch

- Rupture disc: a one time use replaceable valve for rapid pressure relief, used to protect piping systems from extream pressure

- Saddle valve: Used to tap a pipe for a low – flow

- Schrader valve: used to hold the air inside of the tires

- Slide valve: used in old steam engines to control admission and emission of steam from the piston.

- Slide gate valve: Ideal for handling dry bulk material in gravity flow

- Stopcock: restricts or isolates flow through a pipe

- Swirl valve: A specially designed Joule-Thompson valve imparting a centrifugal force upon the discharge stream for improving gas – liquid phase separation

- Tap / faucet

- Tesla valve: A form of check valve with no moving parts

- Thermostatic mixing valve

- Thermostatic radiator valve

- Trap primer

- Vacuum breaker valve: this type of valve prevents the back – siphonage of contaminated water into pressurized drinkable water supplies

Two – Port Valves

Operating positions for 2 – port valves can be either closing the valve so that no flow goes through, valve is open for maximum flow, or sometimes partially open to any degree in between. Many valves are not designed to precisely control inter-mediate degree of flow; such valves are considered to be either opened and closed. Some valves are specially designed to regulate varying amounts of flow. These valves have been called by different names such as regulating, throttling, metering, or needle valves.

Three – Port Valves

Valves with three ports serve with many different functions.

Three – way ball valves come with a T or L shaped fluid passage-ways inside the rotor. The T valve might be used to permit connection of one inlet to either or both outlets or connection of the two outlets. The L valve could be used to permit disconnection of both or connection of either but not both.

Shuttle valves automatically connect the higher pressure inlet to the outlet while preventing flow from one inlet to the other.

Single handle mixer valves produce a variable mixture of hot and cold water at a variable flow rate under control of a single handle.

Thermostatic mixing valves mix hot and cold water to produce a constant temperature in the presence of variable pressures and temperatures on the two input ports.

Four – Port Valves

A 4 – port valve is a valve whose valve body has four ports equally spaced around the body and the disc has two passages to connect adjacent ports. It is operated with two positions.

Control

Many valves are controlled by hand with a handle attached to the its stem. If the handle is turned 90 degrees, the valve is called a quarter – turn valve. Butterfly, ball valves, and plug valves are often quarter – turn valves. If the handle is a full circul with the stem as the axis of rotation in the cente, then the handle is called a hand – wheel. Valves can also be controlled by actuators. They can be electro – mechanical actuators such as an electric motors or solenoids, pneumatic actuators, or hydraulic actuators. Actuators can be used for the purposes of automatic controls such as in washing – machine cycles, remote controls such as the use of a centralised control room, or because of manual control is too difficult for example when the valve is very large. Pilot valves are valves which are used to control other valves. Pilot valves in the actuator lines control the supply of air or liquid going to the actuators.

Search

Recent Posts