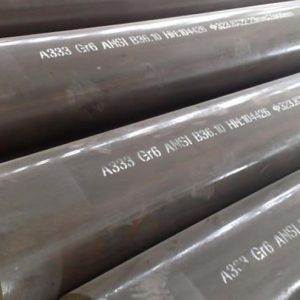

ASTM A335 Pipe (ASME S/A335, Chrome-Moly) is a seamless ferritic Alloy-Steel Pipe for high temperature service.

Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Sometimes referred to as “P Grade”, chome moly pipe is popular in P-Grades P5, P9, P11, P22, and P91.

Kasko Makine Supply stocks a full range of the following A335 pipe grades:

Main grades: ASTM A335 P5, P9, P11, P-22, and P91

Size Range:

NPS 1/4” to NPS 24”

Wall Thickness – Schedules 40 through 160, STD, XS, XXS.

Unscheduled heavy wall pipe thicknesses available up to 4 inches.

General Abbreviations of chrome moly pipe are chrome-moly, cro-moly, CrMo, CRMO, CR-MOLY

ASTM A335 standard is issued under the fixed designation A 335/A 335M; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision.

The most common use of grades P11, P22, and P91 is in the power industry and petro-chemical plants, Grades P5 and P9 are commonly used in refineries.

ASTM A335 is often called as chrome moly pipe because of the chemical contain of Molybdenum (Mo) and Chromium (Cr). Molybdenum increases the strength of steel and Chromium (or chrome) is the essential constituent of stainless steel.

The composition chrome moly alloy steel pipe make it ideal for use in power plants, refineries, petro chemical plants, and oil field services where fluids and gases are transported at extremely high temperatures and pressures.

Applications:

Chrome moly pipe under ASTM & ASME specification A/SA 335 P1, P2, P11, P12, P15, P22, P91, P92, P122 are used for power industries whereas ASTM/ASME A/SA 335 P5, P9 are used for petrochemical industries

– Strong resistance to rupturing at high temperatures and high pressures

– May be used for Hydrogen Sulfide Corrosion Services

– Resistant to cracking from hydrogen attack and embrittlement

– Resistant to hot sulfide corrosion cracking

– Can be used for NACE Applications where sour environments are under high temp and pressure

– Can be used in NACE-MRO 175 Sour Service

– Ideal for creep rupture applications

– Can handle high temperatures with very low elasticity

Certitifcation: Chrome Moly pipe are certified as PER DIN 50049 3.1, EN 10204 3.1/3.2 and NACE MR-0175 & NACE MR-0103

Piping Component Specifications:

– Flanges and forged fittings – A/SA 182 F1, F2, F5, F9, F11, F12, F15, F22, F91, F92, F122 Wrought

– Butt-weld Pipe Fittings – A/SA 234 P1, P2, P5, P9, P11, P12, P15, P22, P91, P92, P122